Other Metals

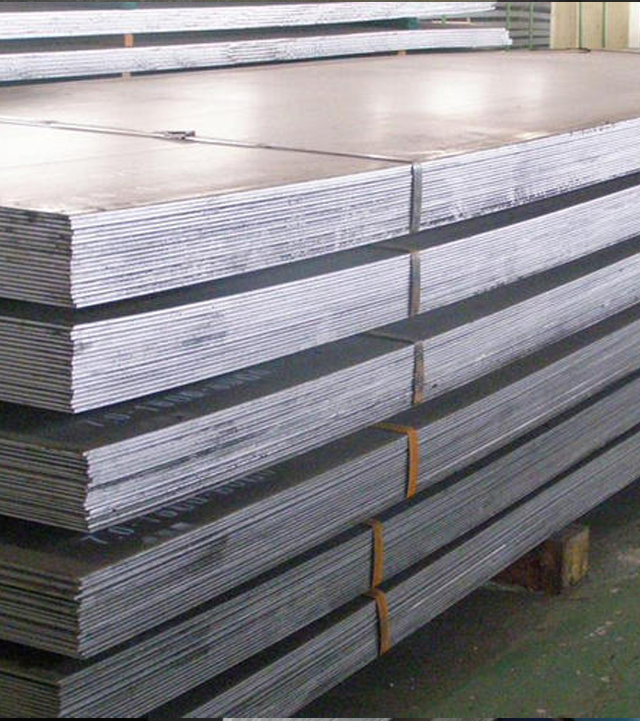

Cold Rolled Steel

Contrary to what the term would imply, cold rolled steel isn’t actually “cold.” Slabs are rolled and processed into their final size and shape after being cooled to room temperature. Superior strength and machinability are features of cold-rolled steel. When precise tolerances, concentricity, straightness, and coated surfaces are required, cold-rolled steel sheets are frequently employed for designing goods. From household goods like refrigerators and washing machines to industrial gear, architectural components, automobiles, and a variety of construction-related products, cold-rolled steel is employed in a wide range of products. Products made from cold-rolled steel include sheet, flat rolls, bars, and tubes.

Galvalume

Galvalume Steel is hot dipped carbon steel with an aluminum-zinc alloy coating that is 55% aluminum and 45% zinc and a small amount of silicon that combines the corrosion protection of aluminum with the galvanic protection of zinc. With its outstanding corrosion resistance and heat reflectivity, the Galvalume steel sheet combines the greatest aspects of aluminum and zinc. It looks great in unpainted applications due to its smooth, silvery metallic appearance. It may be easily repainted in the field or at the manufacturing facility and is also available in the pre-painted form. Use Galvalume metal to add elegant accents to business buildings, rustic and modern houses, or restaurants with an industrial design.

Galvanized Steel

Hot-dip galvanising is the method most frequently used to produce galvanization. In essence, this entails dipping steel parts in molten zinc. The metal items are either dipped or fed into the zinc bath, which permanently bonds with the substrate materials after cleaning them with a mild acid solution. Galvanized is a term frequently used to describe galvanised steel in the manufacturing sector. Regular steel sheets that have been coated in zinc to prevent corrosion are known as galvanised steel. Iron, the primary component of regular steel, rusts when exposed to moisture, such as rain or air humidity. Galvanization is used in a variety of industries to guarantee the quality and security of completed products, including construction, automotive, electronics, shipbuilding, aerospace, and marine.

Hot Rolled P&O

In a continuous hot strip mill, hot rolled sheet steel is rolled at temperatures beginning around 1280°C. The steel travels through roll supports that gradually reduce its thickness to the desired level. The surface of the as-rolled product has a small layer of oxide due to the temperature at which the steel is coiled, which is around 650°C (scale.) It is referred to as “hot rolled black” in this state. Acid pickling is used to get rid of surface oxide in applications where its presence is unacceptable. The sheet is pickled, rinsed, dried, and oiled throughout this process, and is referred to as “hot rolled pickled and oiled” in this state. Common uses include vehicle frames and pipe and tube.

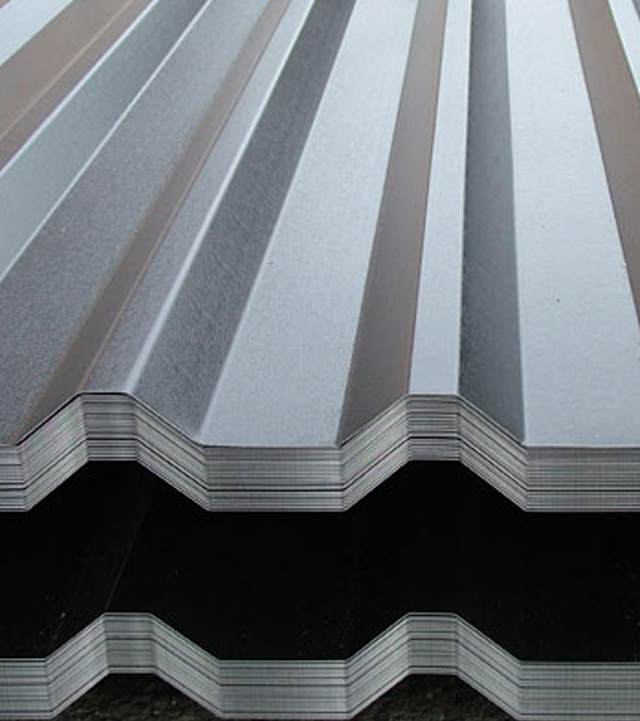

Painted Products

Pre-painted metal is a type of metal on which a coating, such as paint, has previously been applied during the coil coating process. Coil coating is a continuous process that involves unwinding a coil of metal (steel or aluminium are frequent substrates), cleaning and treating the top and bottom surfaces with chemicals, and then priming, painting, and curing the finished product in an oven. There is a vast variety of coatings in use that were created to meet various aesthetic needs as well as provide various levels of performance and durability. Many commercial uses, such as cladding and roofing, residential and garage doors, ceiling grid systems, containers, and large appliances, use painted steel.